What is the basis for purge and trap not having cross-contamination?

Published Time:

2021-01-08

Author:

Source:

Summary

Purge & Trap, a technique used for analyzing trace-level (10^-9 concentration, ppb) volatile organic compounds (VOCs, such as benzenes), was developed in 1974 by chemical expert Tom Bellar of the US Environmental Protection Agency in Cincinnati, increasing analytical sensitivity by 100 times compared to existing methods at the time.

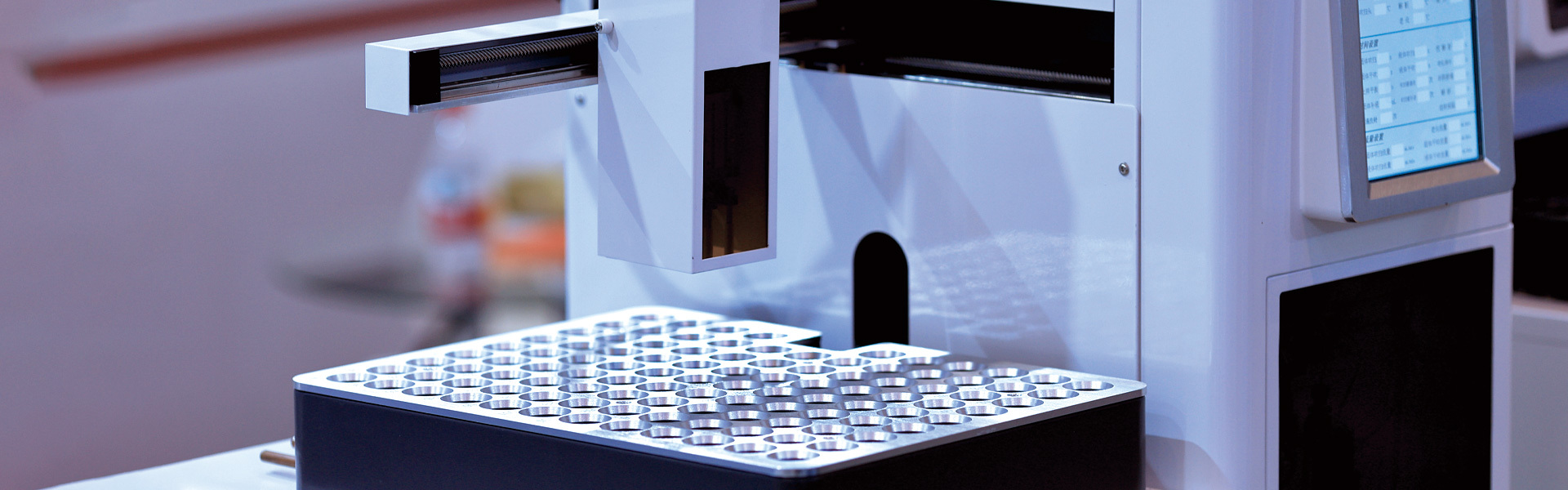

The Acrichi brand of Beijing Juxin Zhuifeng Technology Co., Ltd offers various products such as thermal desorbers, headspace samplers, purge and trap units, and non-methane total hydrocarbon gas samplers. Its purge and trap unit is the Acrichi Automatic Sample Purge and Trap System PTC-76, which has 76 sample positions and can analyze solid and liquid samples; the instrument features inert line connections throughout the entire process, and the trap and purge tube reverse blow gas are separated to reduce cross-contamination between samples; all temperature control links and components can be controlled independently, including the purge tube, six-way valve, sample transfer tube, focusing tube, cold trap, water remover, cleaning distilled water, and solid sample bottles, etc.; the low temperature can reach -40℃.

The purge and trap unit is one of the commonly used sample introduction devices in gas chromatography. Its basic principle is to place the sample to be analyzed (liquid or solid) into a sealable container (purge tube), use an inert gas to pass through the liquid sample (or solid surface) at a certain temperature and flow rate for a certain period, purge out the components to be analyzed, and then enrich (trap) them by passing through an adsorption tube (trap) containing adsorbent material; after the purging and trapping process is completed, quickly heat the adsorption tube (trap) to desorb the adsorbed components, and introduce them into the gas chromatograph with a carrier gas for analysis.

It also has the ability to detect VOCs in water and soil samples, and the innovative gas path design can effectively avoid cross-contamination of water and soil samples.

Water samples and soil samples run in two different gas sample lines, and there is no cross-contamination during the purging process;

Whether water samples or soil samples, the injection needle and sample lines will be cleaned after the operation – 90℃ high-temperature water cleaning. Of course, methanol cleaning can also be enabled, and the entire instrument pipeline can directly run methanol solvent;

Before sample operation, the injection needle will be purged with high-purity carrier gas;

Soil samples are purged directly in a 40ml purge bottle, while water samples are transferred to the purge tube via a syringe and purged in the purge tube, so there is no cross-contamination;

The instrument has two soil analysis modes, allowing self-selection of methods (direct soil purging or automated diluted purging after methanol extraction) to analyze high and low concentration soil samples, avoiding the impact of cross-contamination.

Currently, with the development of the domestic environmental protection industry and the introduction of relevant national standards, the use of purge and trap has become increasingly widespread and common, mainly for determining volatile organic compounds in water, soil, and sediments. In the current domestic analytical testing market, purge and trap device suppliers were mainly foreign manufacturers in previous years, but in the past two years, domestic purge and trap devices have boomed, with many excellent manufacturers emerging.

Keywords:

Intelligent Testing Instruments

Recommended

How to perform injection operation for purge and trap?

2021-02-02

What is the basis for purge and trap not having cross-contamination?

2021-01-08

9 Major Usage Precautions for Gas Samplers

2023-02-23