How to perform injection operation for purge and trap?

Published Time:

2021-02-02

Author:

Source:

Summary

Purge and trap technology, as a sample pretreatment method, has been highly valued by the environmental science and analytical chemistry communities since the 1970s, when scientists first published papers on the determination of volatile organic compounds in water by purge and trap chromatography, due to its advantages such as small sample volume, high enrichment efficiency, minimal matrix interference, and ease of online detection. US EPA standard methods all employ purge and trap technology. Especially with the widespread use of commercial purge and trap instruments, the purge and trap method will play an increasingly important role in the analysis of volatile and semi-volatile organic compounds, and in the speciation analysis of organometallic compounds. Its principle involves continuously passing a purge gas through the sample to extract volatile components, which are then trapped in an adsorbent or cold trap for subsequent analysis. Thus, it is a non-equilibrium continuous extraction. This method can almost quantitatively extract all analytes, not only offering high extraction efficiency but also allowing the analytes to be concentrated, which greatly improves the sensitivity of the method.

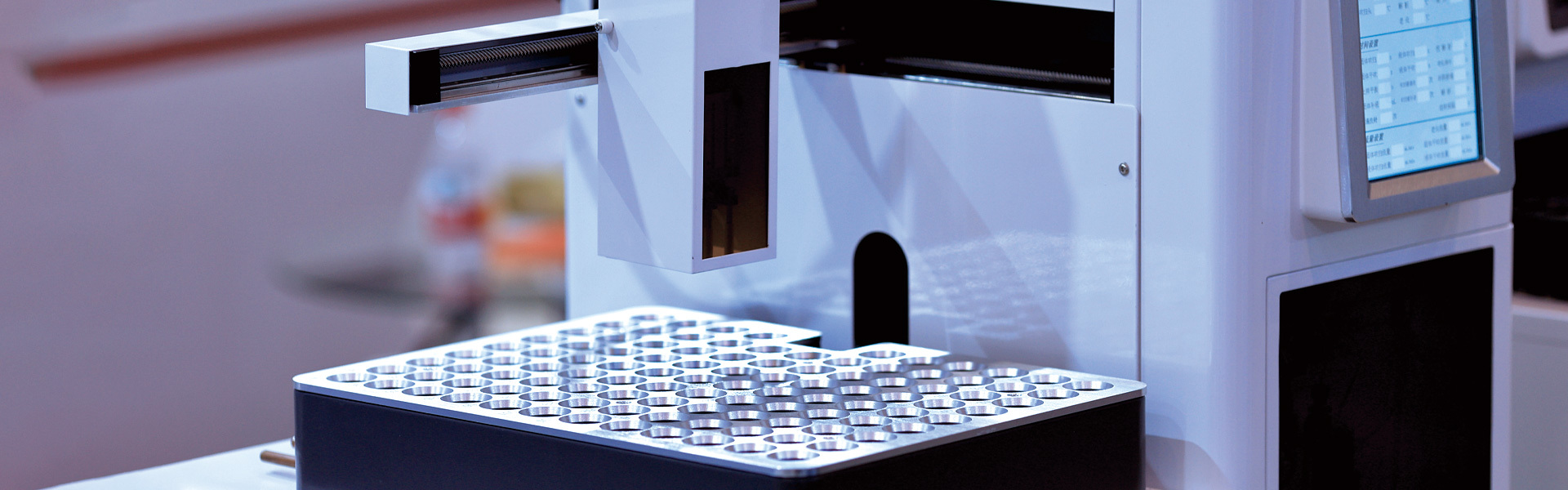

Purge and trap injection operations require a dedicated injection needle. Users can easily remove the syringe plunger, load water samples into the syringe, and directly add internal standards or surrogate samples to the water sample via an injection needle connected to a rotary valve. The injection needle can also be directly connected to the purge and trap valve via a Luer connector. Dedicated purge and trap injection needles can be used for drinking water sample analysis (EPA).

Currently, many international standard methods employ purge and trap technology for sample pretreatment. With China's increasing emphasis on environmental monitoring and higher demands for trace analysis, this technology will find wider application.

Keywords:

Intelligent Testing Instruments

Recommended

How to perform injection operation for purge and trap?

2021-02-02

What is the basis for purge and trap not having cross-contamination?

2021-01-08

9 Major Usage Precautions for Gas Samplers

2023-02-23