9 Major Usage Precautions for Gas Samplers

Published Time:

2023-02-23

Author:

Source:

Summary

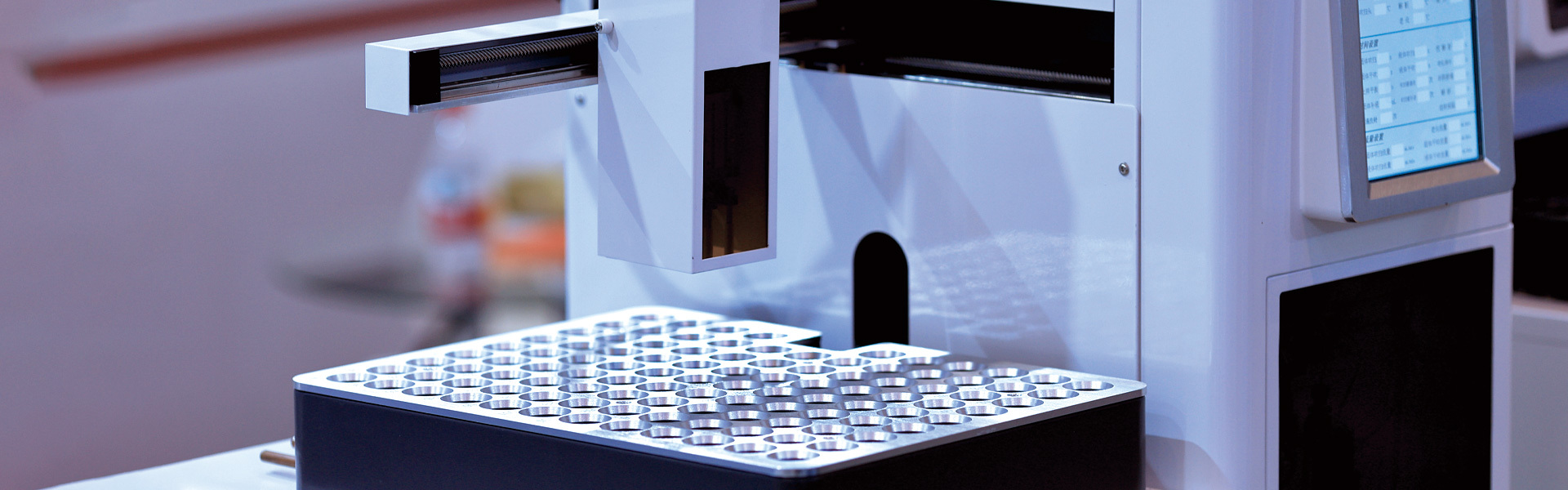

Gas injectors are widely used in chemical and medical fields. Gas injectors are generally made of hydrolyzed glass or borosilicate, with specifications ranging from 1ml to 60ml. Different bottle mouth designs are available to meet various practical operational needs. The bottle caps that match the bottles come in solid and hollow types, with multiple color options. The size of the septa inside the cap varies with the cap size. Septa generally come in one, two, and three layers, with each layer having different or same colors. Septa materials are typically composed of silicone or rubber and PTFE. Suitable for introducing gases such as liquefied petroleum gas and propylene into the pyrolysis furnace of instrument systems for sample component analysis. A unique expansion chamber is used to control the sample at a constant temperature. The quantitative tube ensures the accuracy of sampling, and the window flow meter facilitates monitoring the carrier gas flow. Successfully solved the problem of gas injection volume! It is an injector used on fluorescence sulfur analyzers, chemiluminescence nitrogen analyzers, sulfur-nitrogen analyzers, and coulometers. The injector has an imported six-way valve.

A unique expansion chamber is used to control the sample at a constant temperature. The dedicated quantitative tube ensures the accuracy of sampling, and the window flow meter facilitates monitoring the carrier gas flow. Used for introducing gases such as liquefied petroleum gas and propylene into the pyrolysis furnace of instrument systems for sample component analysis.

Precautions for using gas injectors:

(1) When pressurizing, pay attention that the threads of the lead screw must fully enter the upper plate, and not just be connected by a few turns. This prevents deformation of the lead screw threads.

(2) Regularly add lubricating oil to lead screw 2. This prevents the lead screw from rusting and affecting use.

(3) Pressurization must not exceed the machine's pressure range, otherwise there will be danger.

(4) For laboratory powder tablet presses, it is advisable to use clean No. 46 engine oil; brake fluid must never be used.

(5) If the manual handle 20 feels firm when pressurizing but the pressure gauge 21 shows no indication, immediately unload and check pressure gauge 21.

(6) For new machines or machines that have not been used for a long time, slightly tighten the oil drain valve before use, pressurize to 20~25MPa, then unload immediately, and repeat 2~3 times continuously. It can then be used normally.

(7) The large piston 19 of the laboratory powder tablet press should not exceed a stroke of 30mm.

(8) If the tablet press handle 20 shakes weakly, the pressure gauge does not build pressure, unscrew screw 26, block the low-pressure valve port with your hand, shake handle 20; oil will flow out from 26. When your hand can no longer block the oil coming out of the valve port, tighten screw 26 back into place.

(9) Rock manual handle 11 back and forth to reach the desired pressure.

Keywords:

Intelligent Testing Instruments

Recommended

How to perform injection operation for purge and trap?

2021-02-02

What is the basis for purge and trap not having cross-contamination?

2021-01-08

9 Major Usage Precautions for Gas Samplers

2023-02-23