Application of atmospheric preconcentrator and GC-MS combination in semiconductor manufacturing enterprises

Published Time:

2025-03-16

Author:

Source:

Summary

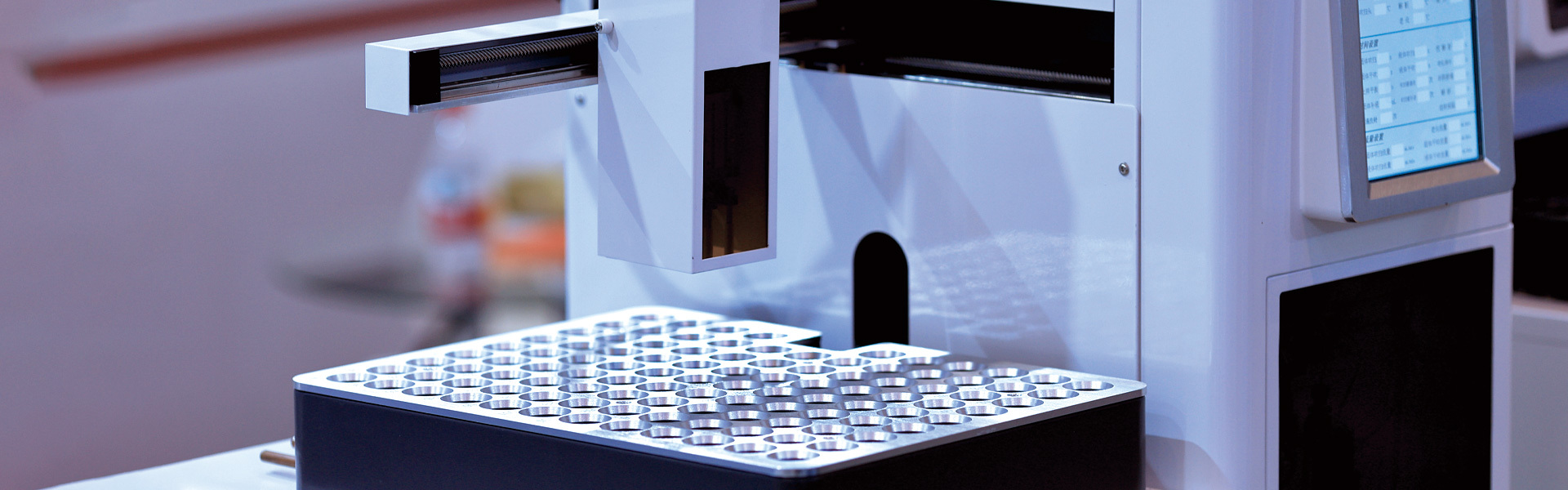

The combination of an atmospheric preconcentrator and a gas chromatograph-mass spectrometer (GC-MS) primarily has two applications in semiconductor factories: 1. During semiconductor production, gaseous molecular contaminants in cleanrooms can deposit on wafer surfaces, affecting device performance and yield. An atmospheric preconcentrator can be used to monitor AMC concentration inside and outside the cleanroom, helping to identify pollution sources; 2. In semiconductor manufacturing, chemicals used (such as cleaning agents, photoresists, etc.) release volatile organic compounds (VOCs), which may negatively impact process and product quality. Utilizing the ultra-low temperature cold trap technology of the atmospheric preconcentrator allows for efficient concentration and detection of trace VOCs.

The working principle of the combination of an atmospheric preconcentrator and a gas chromatograph-mass spectrometer (GC-MS) is as follows: air samples are collected from inside and outside the cleanroom using Summa canisters or sampling bags, then concentrated through a three-stage cold trap preconcentration system. After removing water and interfering gases, the concentrated sample is injected into the gas chromatograph-mass spectrometer (GC-MS) for qualitative and quantitative analysis. This combined analytical system offers the following advantages: 1. It allows for full-volume injection of all VOCs in the air without sample discrimination. For instance, in thermal desorption injection, the adsorption fillers in sampling tubes have varying adsorption effects on different VOCs components, especially poor adsorption for C1-C3 compounds, making the thermal desorption + GCMS combination unable to achieve full analysis of VOCs; 2. The preconcentrator offers relatively flexible injection methods, including Summa canisters, gas bags, and glass injectors. Particularly, if VOCs are collected using Summa canisters, samples can be stored for a long time, and remaining samples after injection can be kept as traceable samples for up to 30 days; 3. The method detection limit can reach PPT level or even lower; 4. Compared to thermal desorption tube sampling, Summa canister sampling is simpler and more convenient. Sampling personnel only need to carry a Summa canister to the designated sampling point, open the valve, and complete sampling instantaneously.

Recommended

How to perform injection operation for purge and trap?

2021-02-02

What is the basis for purge and trap not having cross-contamination?

2021-01-08

9 Major Usage Precautions for Gas Samplers

2023-02-23