The 200°C purge temperature in the purge and trap method is crucial.

Published Time:

2020-12-24

Author:

Source:

Summary

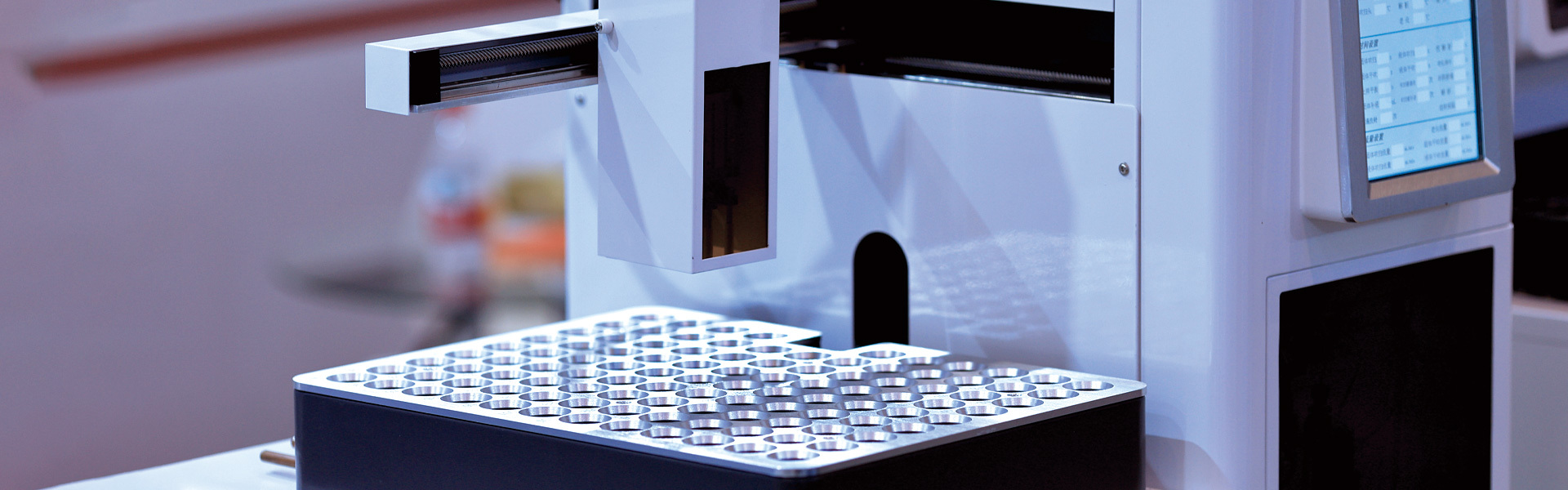

Purge and trap is suitable for extracting volatile or semi-volatile organic compounds and organometallic compounds with boiling points below 200℃ and solubility less than 2% from liquid or solid samples. Purge and trap pre-treatment of samples does not require organic solvents, does not cause secondary pollution to the environment, and has the advantages of small sample volume, high enrichment efficiency, low matrix interference, and easy online detection. However, the purge and trap method is prone to foaming, which can overload the instrument. In addition, the stripping of water vapor is not conducive to subsequent adsorption, makes separation difficult for non-polar gas chromatography columns, and the water in the flame detector can also extinguish the flame.

Purge and trap is highly versatile and can be coupled with most brands of gas chromatographs (GC) and GC-MS; it is simple to operate, easy to use, controlled by computer software, and highly automated. Just place the sample in the sample tray, and all operations are completed by the software, ensuring good sample repeatability. The trap is heated directly, with a heating rate of >1800℃/minute, and users can customize the number of times the sampling and purge tubes are cleaned.

The trap and purge tube are separated by backflush gas, reducing cross-contamination between samples. The sample pathways use PEEK material and silanized inert metal materials to reduce residue contamination. The pipelines and purge tubes can be rinsed with hot water to reduce residue. All pipelines and the six-port valve can be heated with temperature control to eliminate system cold spots, reduce sample loss, and provide synchronous interfaces, allowing the chromatograph and workstation to start simultaneously with injection.

Precautions for Use

1. Temperature Selection

Purge temperature of the sample. Most aqueous solutions are purged at room temperature, and as long as the purge time is long enough, the analysis requirements can be met. Sometimes, to shorten the purge time, the sample can also be heated, but the side effect of increasing temperature is increased water volatilization. For non-aqueous solutions, such as certain meat products, a higher purge temperature is used.

Trap temperature. Here, there are differences between adsorption temperature and desorption temperature. Adsorption temperature is often room temperature, but for gases that are difficult to adsorb, low-temperature cold trapping techniques can also be used, i.e., using cold gas, liquid carbon dioxide, or liquid nitrogen to control the trap tube temperature. As for desorption temperature, it is an important parameter for purge-and-trap technology and should be optimized based on the properties of the analytes and the nature of adsorption. The maximum desorption temperature for commercial automatic purge-and-trap injectors can reach 450℃, but in standard methods for some environmental analyses (such as US EPA methods), a purge temperature of around 200℃ is commonly used.

The temperature of the connecting tubing should be sufficient to prevent sample condensation. The commonly used connecting tubing temperature in environmental analysis is 80-150℃.

2. Purge Gas Flow and Purge Time

The purge gas flow rate depends on the concentration of the analytes in the sample, their volatility, their interaction with the sample matrix (such as solubility), and their adsorption capacity in the trap tube. When using helium, the flow rate ranges from 20-60 ml/min. When using nitrogen, it can be slightly higher, but the purging effect of nitrogen is not as good as helium. The reason is that nitrogen has higher solubility in water than helium. Note that too high a purge flow rate can affect sample collection and lead to loss of sample components.

The carrier gas flow rate during desorption mainly depends on the chromatographic column used. For packed columns, it is 30-40 ml/min; for large-bore columns, it is 5-10 ml/min; for conventional capillary columns, the carrier gas flow rate should be set according to split or splitless mode.

Purge time is one of the important parameters of purge-and-trap technology and must be optimized according to the specific sample. In principle, the longer the purge time, the higher the analytical reproducibility and sensitivity. However, considering analysis time and work efficiency, the shortest possible purge time should be chosen while meeting analysis requirements. In practice, the purge time can be determined by measuring the recovery rate of standard samples.

The steps for purge-and-trap gas chromatography are as follows:

(1) Add a certain amount of sample to the purge bottle;

(2) Introduce purged gas, dried and purified by silica gel, molecular sieve, and activated carbon, into the purge bottle at a certain flow rate to strip volatile components;

(3) The stripped components are retained in the adsorbent or cold trap;

(4) Open the six-port valve to place the adsorption tube in the analytical flow path of the gas chromatograph;

(5) Heat the adsorption tube to desorb it, injecting the volatile components into the analytical column;

Keywords:

Intelligent Testing Instruments

Recommended

How to perform injection operation for purge and trap?

2021-02-02

What is the basis for purge and trap not having cross-contamination?

2021-01-08

9 Major Usage Precautions for Gas Samplers

2023-02-23