Introduction to two application examples of Purge and Trap device

Published Time:

2021-01-04

Author:

Source:

Summary

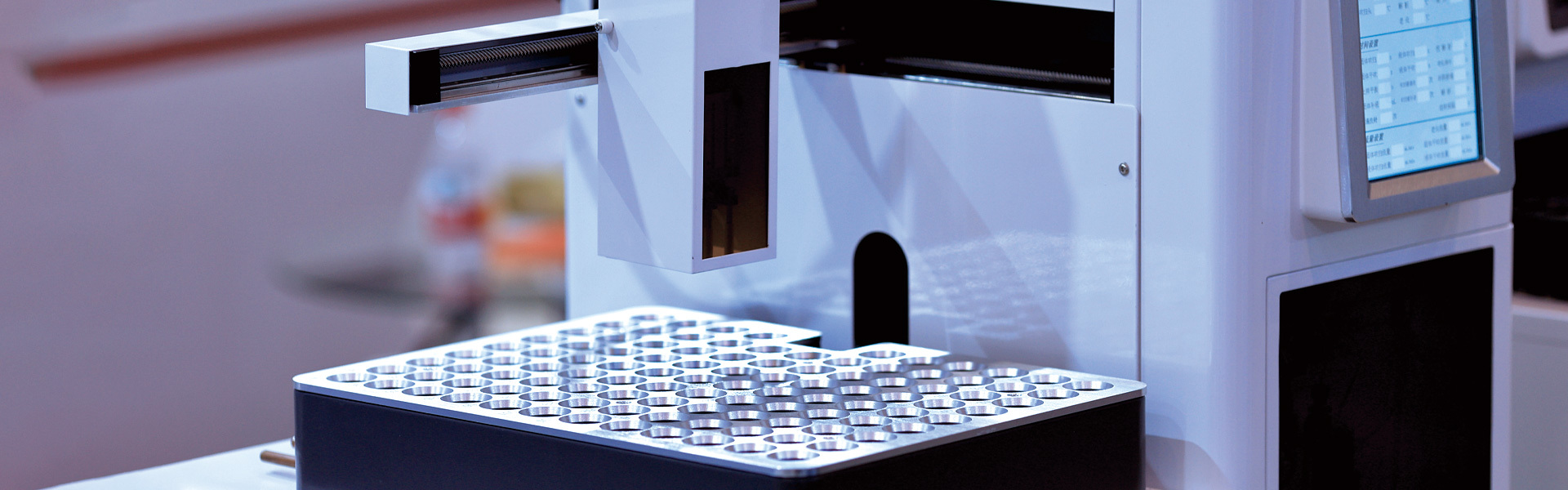

Purge and trap (P&T) is one of the commonly used sample introduction devices in gas chromatography. Its basic principle is to place the sample to be analyzed (liquid or solid) into a sealable container (purge tube), use an inert gas at a certain temperature and flow rate to pass through the liquid sample (or solid surface) for a certain period, purge out the components to be analyzed, and enrich (trap) them by passing them through an adsorption tube (trap) containing adsorbent material. After the purging and trapping process is completed, the adsorption tube (trap) is rapidly heated to desorb the adsorbed components, which are then carried into the gas chromatograph by a carrier gas for analysis.

With the development of the domestic environmental protection industry and the promulgation of relevant national standards, the use of purge and trap technology has become increasingly widespread and common, mainly for the determination of volatile organic compounds in water quality, soil, and sediments. Many standard methods adopt purge-and-trap technology for sample pretreatment. As China places more emphasis on environmental monitoring and has higher requirements for trace detection, this technology will be more widely applied.

Two application examples:

1. Methyltin speciation analysis

This technology was combined with hydride generation (HG)-gas chromatography (GC)-flame photometric detector (FPD) for the quantitative determination of methyltin species in water samples. The optimized purge and trap conditions were:

Purge gas nitrogen flow rate: 30mL/min, pre-purge 5 min;

Purge time: 12 min;

Cold trap temperature: -100℃;

Thermal desorption temperature: 200℃;

Desorption backflush gas flow rate: 40mL/min, purge 5 min;

PTI injection port temperature: 100℃.

Under optimal reaction and instrumental conditions, chromatographic separation of various methyltin species (all at 1 ng/mL concentration) was performed by reaction purging in a 15mL purge bottle. The relative standard deviations for ten determinations of monomethyltin, dimethyltin, and trimethyltin were 2.1%, 2.8%, and 3.5%, respectively. This method can be used for the determination of methyltin in seawater near wastewater treatment plants.

2. Methyl tert-butyl ether (MTBE) determination

This technology was combined with gas chromatography (GC)-flame ionization detector (FID) for the quantitative determination of methyl tert-butyl ether in unleaded gasoline additives. The optimized purge and trap conditions were:

Purge gas nitrogen flow rate: 40mL/min, pre-purge 5 min;

Purge time: 10min;

Cold trap temperature: -75℃;

Thermal desorption temperature: 200℃;

Desorption backflush gas flow rate: 40mL/min, purge 5 min;

PTI injection port temperature: 100℃.

This method can be used for the determination of methyl tert-butyl ether in soil samples near gas stations.

Keywords:

Intelligent Testing Instruments

Recommended

How to perform injection operation for purge and trap?

2021-02-02

What is the basis for purge and trap not having cross-contamination?

2021-01-08

9 Major Usage Precautions for Gas Samplers

2023-02-23